The Advantages of V-Port Ball Valves for Throttling Control

Precise flow control is critical across industries like chemicals, oil and gas, power generation, and more. Throttling valves allow processes to be maintained at desired conditions by restricting flow and regulating pressure. For decades, globe-style valves have been the go-to solution for throttling applications, but modern V-port ball valves offer significant advantages. Below are some applications in which V-Port Ball Valves can be used.

| V-Port Ball Valve Applications | ||||

|---|---|---|---|---|

| All Steam Lines | Plate Heat Exchangers | Glycol Tracing Lines | Gas Lines | Cooling Water Systems |

| Level Control | Turbine Lubrication Systems | Boiler Lines | Bleaching Chemical Lines | Fuel Oil Systems |

| Wastewater System Lines | Agriculture Chemical Lines | All Processing Lines | Atomizer Misting | Commercial/Industrial Water Heaters |

| All Heat Transfer Lines | All HVAC Applications | Feed lines to any liquid operated equipment / machinery | Pump Recirculation | Geothermal Applications |

| Desalination Lines | Fuel Metering | Water Separation | Pressure Reduction | Blow Down Lines |

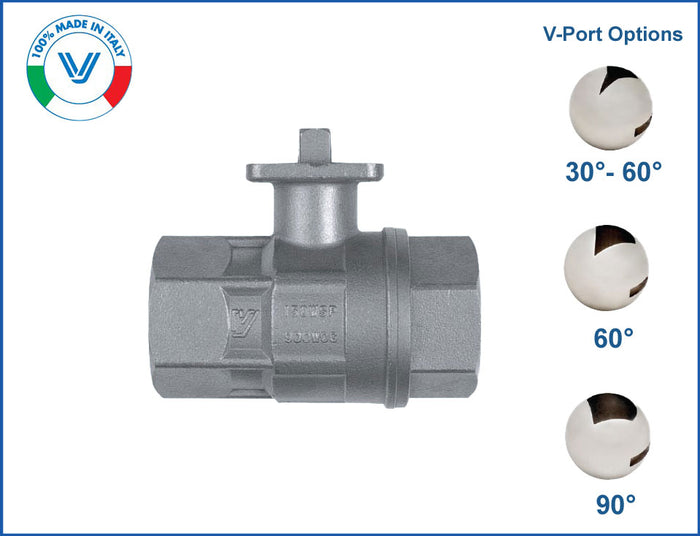

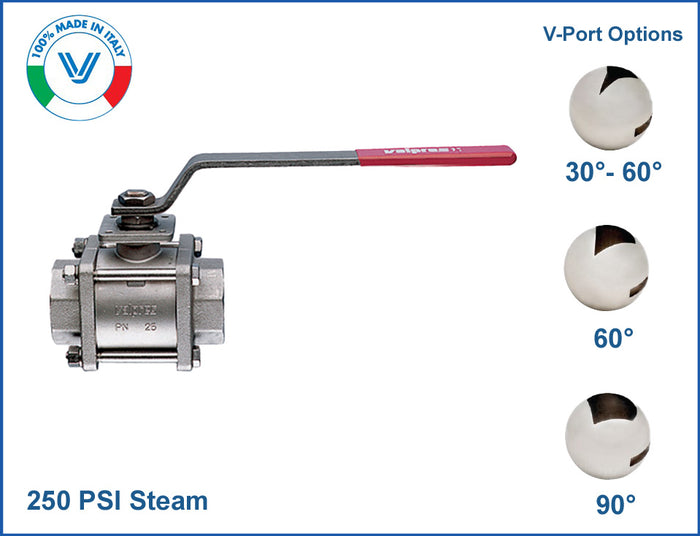

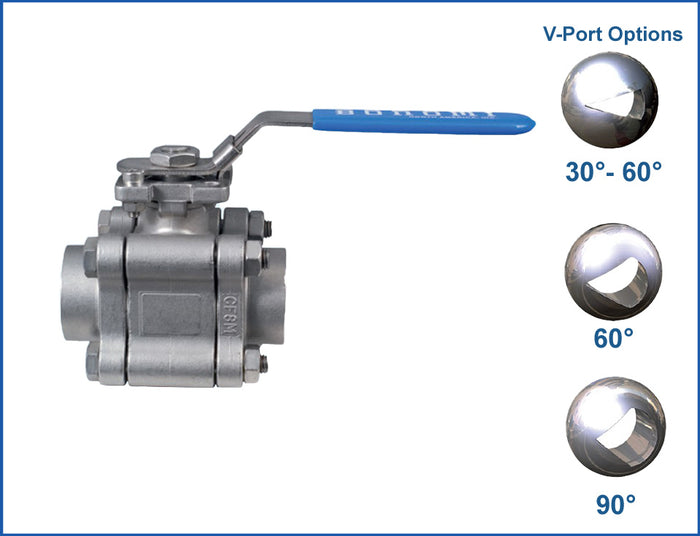

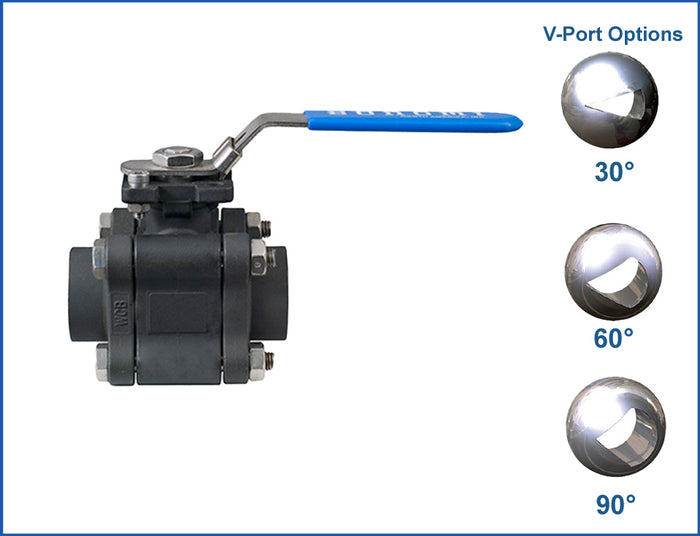

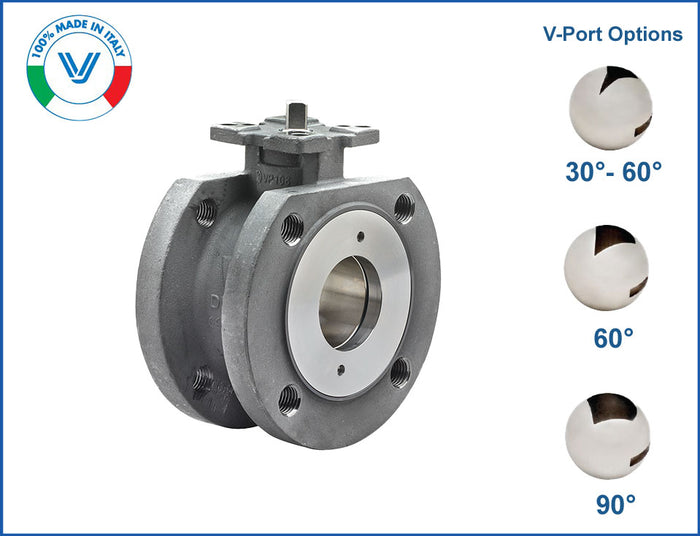

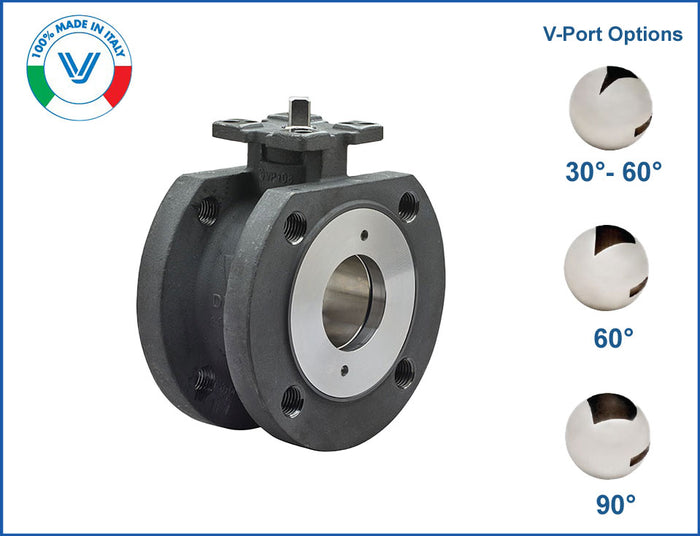

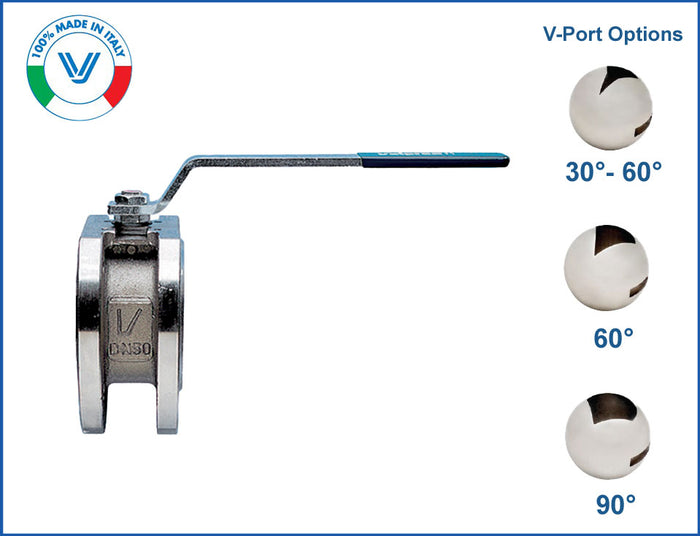

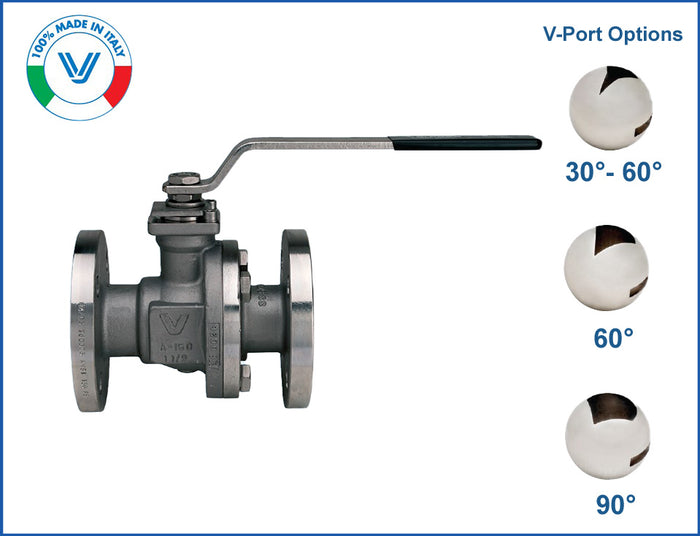

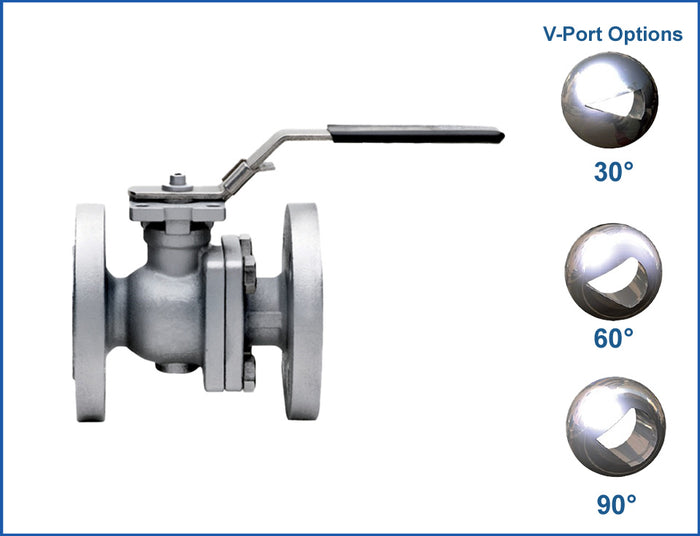

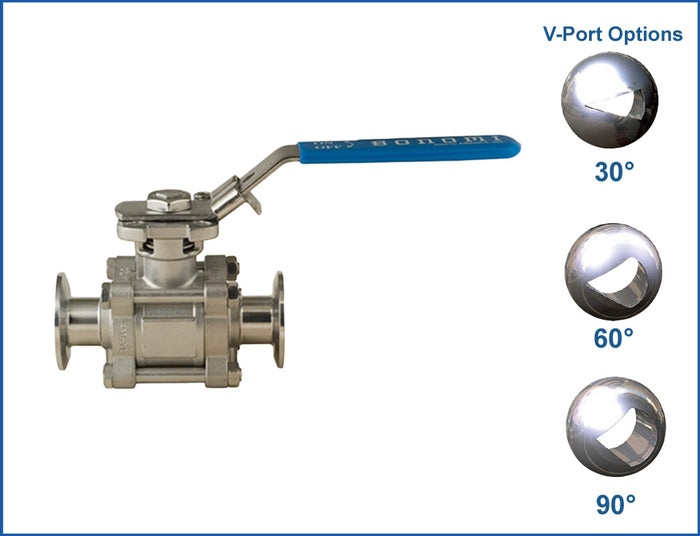

See Available V-Port Valve Options

Throttling Challenges With Globe Valves

Globe valves have been widely used for throttling because of their sturdy construction and ability to control flow. However, their design has inherent drawbacks that limit performance:

- Wire draw - Tight flow constriction causes pressure drops and trim erosion over time. This degrades accuracy.

- Cavitation - Insufficient recovery factors increase potential for damaging cavitation to occur.

- Noise - High velocity flow and cavitation lead to excessive process noise.

- Rangeability - Inherent recovery factors of around 70% limit turndown capabilities.

- Higher torque - Greater actuation forces required to stroke the linear plug.

- Flow direction - Must be installed in line with process flow for proper operation.

The linear plug motion and right-angle flow path of globe valves lead to these issues that prevent precise, high-performance throttling control.

V-Ball Valve Advantages

V-ball valves overcome these limitations with an innovative spherical v-notch design:

- Graduated V-notch - Provides smooth increase in flow area and higher recovery factors over 80%. This reduces pressure drop, turbulence, and possibility of cavitation.

- Compact size - Allows fast response and minimal actuated torque requirements.

- Streamlined flow - The uninterrupted flow path with no sharp contractions minimizes erosion and noise.

- Anti-cavitation cages - Multi-stage pressure zones prevent localized vaporization and damage.

- Lower maintenance - Absence of packing and rising stems eliminates friction and leakage issues.

- Installation flexibility - Ball swiveling action allows installation in any orientation.

- Tighter shutoff - Metal seating provides bubble-tight shutoff when required.

- Higher capacity - Less flow restrictions allow control of higher flow rates in smaller sizes.

Cost benefits of switching to V-Port Ball Valves

Lower Maintenance Costs:

- V-balls eliminate ongoing packing adjustments and repacking labor common with rising stem globe valves.

- Rotary operation produces less wear over time compared to stroking action in globes, reducing repair frequency.

- Cavitation resistance allows for longer service life before trim replacement is needed.

Energy Savings:

- The lower pressure drop through a V-ball results in less wasted pumping energy compared to a higher loss globe valve.

- Tighter shutoff can reduce steam trap leakage and product loss.

Compact Installation:

- Smaller, lighter V-balls require less structural support and simplify piping layouts.

- Wafer or flanged short pattern designs take up less space than globes.

Lower Actuation Requirements:

- The smooth rotary motion needs smaller, less expensive actuators and associated wiring.

- No need for heavy-duty actuators required to stroke globe valves.

Safety and Environmental:

- Lower emissions and leakage mean less impact on environment and surrounding communities.

- Improved process control results in fewer emergency shutdowns.

In Summary

The superior throttling abilities of V-ball valves make them the ideal choice to meet today's precise process control challenges. Their advanced flow geometry and capabilities represent the future of throttling valve technology.

Proper Sizing and Selection

Working with advanced V-ball sizing software, the team at CONTROL VALVES ONLINE can model real-world conditions and recommend ideal valves from our extensive valve selection for each application. Our team of engineers work closely with customers to ensure optimal selection and performance.

Whether you need a compact 2-piece or 3-piece split body design, We offer a comprehensive V-ball valve selection to suit your precise throttling requirements. With advanced valve sizing tools and knowledgeable support combine to simplify the transition to V-ball technology.

Contact us today to evaluate your throttling application and improve flow control with V-ball technology or or fill out our application survey to receive your comprehensive flow control valve sizing report.